ZIMBA’s First Six Months: Key Insights and Challenges from Work Package 1

22.07.2025

Introduction

The ZIMBA project, focused on enhancing Absorption Heat Transformer (AHT) systems, has made significant strides in its initial phase. This article highlights the key activities and results achieved within the first 6 months, emphasizing environmental challenges, end-user requirements, and architectural studies conducted to optimize AHT systems.

Raising Awareness of Environmental Challenges

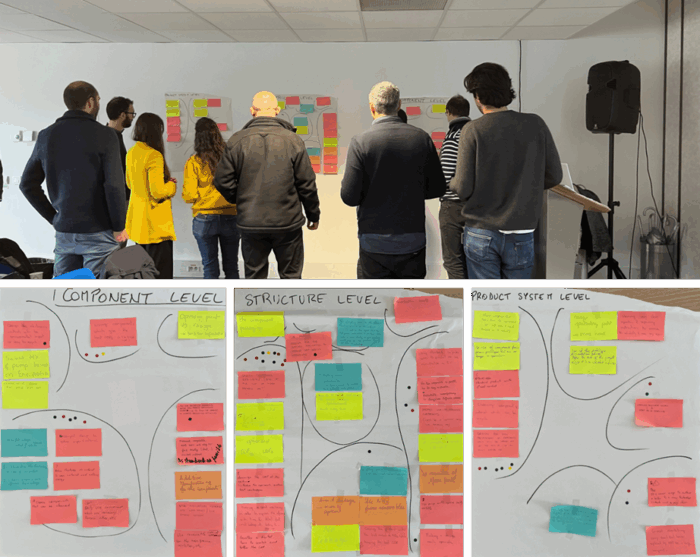

One of the primary objectives was to integrate an eco-design approach into the project’s development. An eco-design workshop was organized by CEA to present eco-design concepts, methods, and tools. Participants were informed about both global environmental challenges and those specific to the AHT technology.

A preliminary Life Cycle Assessment (LCA) performed by POLIMI helped identify the system’s key environmental hotspots. Using the eco-design wheel tool, a brainstorming session was conducted to generate ideas at the component, product structure, and product system levels, covering the entire life cycle. This session resulted in 45 ideas for an optimized design, which were categorized and prioritized based on their attractiveness in reducing environmental impact, ease of implementation, and innovative potential. Eighteen ideas were selected for further analysis in Task 4.4 Evaluation.

Collecting End Users’ Requirements

To ensure that the AHT system meets real-world needs, extensive efforts were made by OST to collect the requirements of end users.

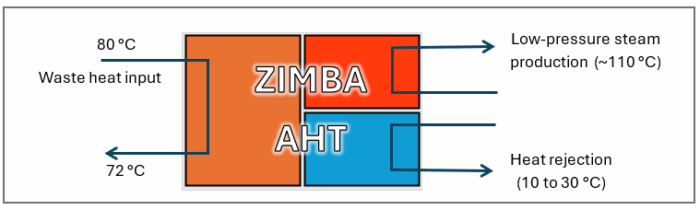

Successful integration of the AHT requires suitable temperature levels, continuous thermal demand, and an excess of waste heat. The aim is to target applications where waste heat at approximately 80/72 °C is available and there is a low-pressure steam demand.

For the ZIMBA AHT, the availability of driving waste heat at 70 to 80 °C remains the primary constraint. This temperature range is particularly prevalent in the refinery sector, with additional potential in the chemical, paper, and food industries. Waste heat in the 60 to 80 °C range is also found in power generation (e.g., engine cooling), suggesting broader opportunities for low-temperature heat recovery, bearing in mind that the cooling water temperature must be proportionally lowered to avoid a significant reduction in performance if the vapour generation temperature is kept constant.

An online questionnaire was established for CLAUGER Sales Representatives to gather specific demands and waste specifications from potential end users. Interviews were conducted with key industries to understand their temperature conditions and heating/cooling requirements.

Architectural Studies for Baseline and Upgraded AHT Systems

POLIMI simulated two main AHT cycle configurations to determine the best architecture for the ZIMBA project. The results indicate that the configuration incorporating a rectification section is not viable due to excessive pressure levels observed under off-design conditions, reaching up to 36 bar(a) at elevated condenser inlet temperatures. These pressures are close to practical operating limits.

The baseline AHT configuration without a rectifier, which operates with ammonia vapor of lower purity, maintains significantly lower operating pressures while achieving remarkable performance at nominal conditions. At a design point of 20 °C water inlet temperature at the condenser (for heat rejection), the system delivers a heating capacity of 15.1 kW, a thermal COP of 0.46, and an electrical COP of 37.9.

Simulations also reveal performance degradation under off-design conditions, particularly when the temperature of the cooling water rises in summer, which can only be mitigated by significant variations in working fluid concentrations. Allowing for such large variations would require large storage vessels upstream of the pumps, introducing substantial technical and safety challenges. However, the integration of an ejector opens up new possibilities for addressing these challenges and limiting the performance degradation associated with an increase in cooling water temperature.

Conclusion

The ZIMBA project has made significant progress in integrating eco-design principles, collecting end-user requirements, defining typical integration schemes and conducting architectural studies for AHT systems.

Stay tuned for more updates as the ZIMBA project continues to innovate and improve AHT systems for a sustainable future.